REVERBERATORY FURNACES

Columbia Specialty Metals uses two state of the art reverberatory furnaces to melt only high purity aluminum. The addition of a second furnace in 2011 increase our capacity plus provides a contingency for equipment failure.

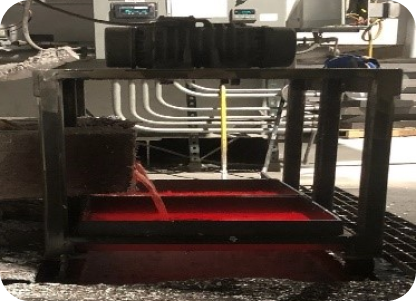

CASTING PIT

The casting pit is where the molten aluminum is cast and cooled into pellets by carefully controlling the operational parameters.

KILN DRYER

Columbia Specialty Metals uses a rotary kiln dryer to remove all moisture from the pellets and to screen the pellets after drying to ensure proper shape and size.